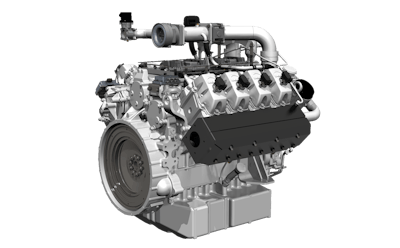

TEDOM offers a new low-emission engine with continuous duty features. This new engine has a power output of 185kW, filling the gap between 150kW and 275kW engines currently available on the market.

While developing the engine, the company took into account possible future shifts in fuel composition. One significant change anticipated is the injection of hydrogen into the natural gas grid, which could potentially reduce the Methane Number below MN80—the minimum value required by many turbocharged engines. For the new engine was therefore chosen a Naturally aspirated stoichiometric concept. This choice gives the best preconditions to reach the lowest emissions and to utilize the fuels with lower knock resistance at the same time.

Stoichiometric engines can fully reach their low emission potential only when Air-Fuel-Ratio is properly controlled. Therefore, the new engine is equipped with an improved Bosch engine management system that incorporates an accurate Air-Fuel-Ratio control strategy. AFR control is based on two lambda sensors, one upstream and the second downstream of the three-way catalyst. Such system is able to meet strict emission limits and reach desired emission stability.

The improved engine control system also incorporates other new functions. One new feature is misfire detection, which is capable of detecting each individual misfire and recognizes faulty sparkplugs to prevent potential emission spikes or catalyst damage. Another new function is knock detection. This integrated function is sensitive and protects the engine against damage caused by knocking.

This new engine has passed extensive in-house durability tests before release. After initial development in 2019 engine has already collected over 25,000 operating hours during in-house durability test for optimization of details and service schedule verification.