Enerpac has announced the launch of the new PPH-Series Hydraulic Pin Puller, providing a safe and versatile method for removal of joint pins during the maintenance of heavy machinery. These complete kits use hydraulic power to remove joint pins on excavators and diggers used in the construction industry.

Until now, operators have relied on pin removal using unsafe methods, such as torching, lancing or hammering, all of which risk irreparable damage to the joint pin. With a pulling capacity of 40 to 66-tons, the PPH-Series Pin Puller provides safe removal of joint pins up to 11.9 in. long. It uses a powerful, Enerpac hydraulic cylinder to extract pins with precision and minimal damage, allowing a single operator to remove a multitude of joint pin sizes.

Safe Pin Pulling

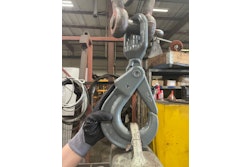

Supplied in a portable, wheeled carry case, the PPH-Series Pin Puller Kits, PPH40 and PPH66, are designed to handle a diverse range of pin-pulling tasks. Each set includes three stacking and locking patented C-Sleeves, with the option of adding an extra two for longer pins up to 20 in. long. The C-shape design creates a fitment around the flag of heavy machinery pins, providing precise and safe pin removal.

Improving operator safety, each kit contains a shackle for lifting via a crane or lifting system. The column sections have multiple hoist points, designed to give the user control over the balance of the tool while it is suspended. The kit also contains a Quick Nut for fast attachment to threaded rods, with alternative thread sizes available to purchase separately.

Enerpac

Enerpac

Damaged Nut Threads

The innovative split Quick Nut makes it possible to manipulate damaged threads. The one-handed closure is quick to assemble around a rod and avoids running the nut over damaged threads.

“Safety on the job site is paramount, which is why these kits offer a safer alternative than old-school, traditional methods involving sparks, heat, hammering, and loose parts. We wanted to provide a safe and efficient way for a single operator to extract pins from construction vehicles that eliminated damage to parts, but also provided a lightweight and potable tool that was practical to move about on-site. The transport and assembly of the PPH-Series Pin Puller Kits is made easier by the robust aluminum construction of the Enerpac Hydraulic Cylinder,” said Ejnar Christensen, national accounts manager, Enerpac.

Each PPH-Series Kit includes three column sections that lock together. Multiple column sections can be stacked together depending on the length of the joint pin. Up to maximum five Column Sections can be locked together.