When people talk about automation in paving, I've noticed that the conversation usually veers toward extremes. Either we’re moments away from handing over the job to machines, or we’re still decades off from anything more than some fancy sensors and buzzers. It's not surprising that the reality is a bit messier.

While I was at World of Asphalt 2025 in St. Louis, MO, I had a distinct mission in mind at each booth I visited. I wanted to get an understanding of where exactly is the industry in terms of real automation. Where is the line? How close are we to it? That's why so much of this issue is dedicated to the topic.

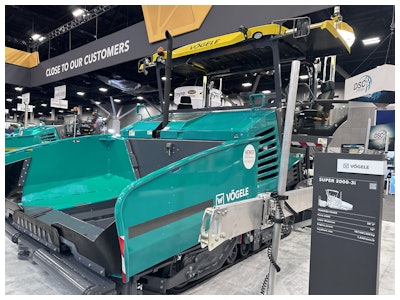

This included a stop at the Wirtgen Group booth to talk to about Vogele’s latest machine control systems. I sat down with Laikram Narsingh, Product Manager at Wirtgen, who’s been walking the line between machine automation and human judgment long enough to see through the hype. What followed was a refreshingly honest conversation about what today’s paving automation can actually do—and just how far we really are from a truly “autonomous” paving future.

A Symphony of Systems

According to Narsingh, modern paving automation breaks down into several core functions.

“In terms of automation,” he explained, “we’re talking about controlling the machine in terms of depth, width, and direction.”

These parameters can now be dialed in with remarkable precision using machine control paired with GPS positioning systems—most often provided by third-party vendors like Topcon or Trimble [both featured in this year's Big Tech Roundtable].

That conversation between systems is key. These days, more and more paving projects today are designed with a 3D model in mind—a digital blueprint that tells machines where the pavement needs to go, how wide it should be, and how deep to lay it. Once a positioning system reads that model, it feeds that information to the paver, like Vögele’s onboard controls, which take over the execution.

So, in a sense, once everything’s set, the machine can handle the dimensional execution—depth, width, and direction—with minimal input. But that’s only one layer of the job. Anyone who's been in the industry for more than five minutes, understands that isn't covering everything.

Playing Nice, Playing Together

Automation doesn’t stop at just the geometry. Another major variable is the flow of material itself—how much mix is being laid down, and how consistently it’s being fed across the screed.

“One of the five forces that affects grade is the amount of material in front of the screed,” said Narsingh. “So we have automation that delivers the right amount of material to keep that force constant.”

Another system monitors the height of the mat, ensuring that even if the volume and depth are correct, the final ride quality meets spec.

That’s at least two independent systems—geometric control and material flow control—each automated but still reliant on human input to calibrate and verify.

At this point, I asked Narsingh flat out: if all of these systems are working together, and assuming everything is properly calibrated, could a single operator manage a paver this size?

“Theoretically, yes,” he said, then immediately laughed. “But we all know—shit will happen.”

There may be no truer-truth in the asphalt industry. Anyone who’s been on a jobsite knows exactly what he means. Automation may be able to control things under the ideal conditions, but real life is built on anomalies. Unexpected grade shifts, changing weather, inconsistent truck deliveries—none of that is in the model.

“You always want at least one guy up front and one guy in back. Because no matter how automated things get, somebody’s gotta keep eyes on it,” he said. “At the end of the day, someone needs to verify that the depth coming out matches what the model called for.”

It’s a simple, and ironically, human truth: automation is only as good as the person watching it work.

Compatibility vs. Complexity

One of the more interesting parts of our discussion revolved around software compatibility. Vögele doesn’t make GPS systems, but they’ve gone out of their way to make sure their equipment can interface directly with third-party systems without the need for a tangle of extra controllers and sensors.

“If the guy buys a Topcon system,” Narsingh said, “he just tells them he’s using a Vögele, and their system can plug directly into our machine.”

No expensive adapters, no Frankenstein’d custom setups, and no extra software licensing traps that hold contractors hostage to proprietary platforms. This kind of openness is a big deal. Because when you’re out there on a real job—trying to get the mat down while traffic whips past at 70 mph—you don’t want to be troubleshooting your USB dongle.

Complexity vs Coordination

I pressed Narsingh on a question that’s hovered over every tech show and demo I’ve attended this year: If we’ve had 3D control for twenty-five years, and all these systems can already operate semi-independently, why aren’t we further along or closer to fully integrated automation control systems?

He didn’t hesitate.

“You’ve got a paver, you’ve got to heat the screed, you’ve got to get it to the jobsite. Who does that? A human,” he said. “Sure, all the individual parts can be programmed. You could warm up the hydraulics with a pre-set schedule. But to do that, now you’re adding so many sensors, so much complexity, it’s just not practical.”

He’s not wrong. There’s a difference between what’s technically possible and what’s operationally and financially viable. And as he pointed out, even the most advanced systems still require someone to physically install and maintain them.

Take the road scan system—a high-end camera that takes readings every 12 inches of mat laid.

“It’s a very expensive camera,” Narsingh noted. “You could design one to be waterproof so you can just leave it on—but now you’re talking another $100,000 just to eliminate one more manual task.”

The picture of automation coming into view, the future of the industry, is augmented human capability and efficiency, not human replacement.

Interdependence And The Human Link

By the end of our conversation, it became clear that the real challenge isn’t the lack of automation—it’s the challenges of integration.

“All the interdependent systems—which can individually be automated and already are—require the human to be the intermediary,” I summarized while standing next to the giant Super 2000-3i paver. “Because the three or four different automated systems go through the human. Without that person, you'd need to create a piece of hardware and software that does all that communication for you—and we're not there yet. We may never be there, and me never need to be there, for that matter.”

Narsingh nodded. “Exactly. Interesting, right?”

It is. Because it turns the automation narrative on its head. The future of paving may be automated, but it will still have boots on the ground. Not because the technology isn’t good enough, but because the job is too dynamic, too complex, and too interconnected to be fully scripted by software.

And maybe that’s not a problem. Maybe that’s the point.