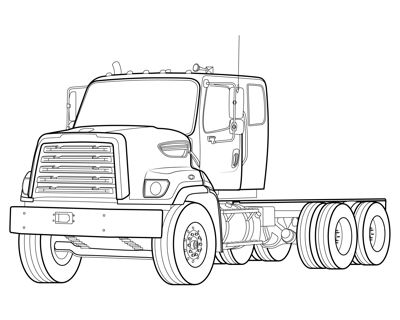

We've applied sophisticated engineering to the structural elements of our work trucks. First, our cabs are light - weight, yet extremely tough. Corrosion-resistant aluminum is reinforced with e-coated steel and assembled to precise manufacturing tolerances with Henrob rivets and welded construction. This process produces a durable and safe cab that meets stringent A-pillar impact, rollover, and back wall impact tests. Plus, the vocational chassis includes a robust backbone with a complete offering of single- and double channel frame rails. The result is a tensile strength of up to 120,000 psi and an RBM ratio up to 3.7 million inch-pounds per rail. This means the 108SD can handle whatever job is thrown at it, day after day, year after year.

Corrugated floor, roof, and back-of-cab panels for added strength

Meets Swedish A-pillar test standards and SAE J2422 roof strength requirements

Available in day cab, extended cab or 4-door crew cab configurations

2,500 sq. in. one-piece windshield for outstanding job site visibility

Wide-door openings with low step-in height for safe entry and exit

Steel firewall for solid mounting of dash panel and driver control