As with operating any type of heavy equipment on a job site, the worker’s apparel is critical to safety, comfort, productivity, and efficiency. From head to toe, here are factors to consider when choosing proper workwear when operating an excavator.

Hard Hat or Safety Helmet

A hard hat or helmet is worn when working in areas where there is possible danger of head injury from impact, falling or flying objects, or from electrical shock and burns. Specialty hard hat types include those that accommodate miner's light attachments, reflective stripe for night work, and attachments for visors or earmuffs.

ANSI Z89.1, American National Standard for Personal Protection - Protective Headwear for Industrial Workers establish hard hat requirements. The University of Iowa’s Environmental Health and Safety notes the suspension system inside the hat is designed to help absorb and dissipate impact while keeping a clearance between the head and shell of the hat. Type 1 helmets are intended to reduce the force of impact resulting in a blow only to the top of the head. Type 2 helmets are intended to reduce the force of impact resulting in a blow to the top and the side of the head.

Class E helmets are for use where electrical hazards are present that are non-conducting and intended to protect against falling objects and reduce the danger of exposure to high voltage electrical shocks and burns. They offer the highest protection with high-voltage shock and burn protection up to 20,000 volts. Class G general use (limited voltage - non-conducting) helmets are intended to protect against falling objects and reduce the danger of exposure to low voltage electrical conductors, providing impact and penetration resistance and protection from up to 2,200 volts.

Class C hard hats are not tested for electrical resistance or intended to provide protection from electrical conductors, but are designed for lightweight comfort and impact protection. Hard hat headbands and chin and nape straps should be adjusted to keep the hat comfortably on the head. Liners or sweatbands can be added for warmth or cooling, the university notes.

Safety Glasses, and Ear Protection

Safety glasses serve to protect the eyes from the materials which may become airborne when working on an excavation job site. A U.S. Bureau of Labor Statistics survey of workers suffering eye injuries showed nearly three out of five were not wearing eye protection at the time of the accident, indicating they believed protection was not required for the situation. Optimal safety glasses provide high levels of UVA/ UVB/UVC protection and comply with the ANSI / ISEA Z87.1+ standard for personal eye protection.

Earplugs or ear muffs act to mitigate potential hearing damage as a result of prolonged exposure to heavy machinery noises from within the excavator and from other heavy machinery on the jobsite. The Occupational Health and Safety Administration indicates employers need to implement a hearing conservation program when noise exposure is at or above 85 decibels averaged over eight working hours or an eight-hour time-weighted average. Consider the average decibel rating for lawnmowers, for instance, is 80 to 100 dBA.

Outerwear and Work Boots

High-visibility apparel to cover the trunk area gives others on the jobsite a visual cue of a worker’s presence to reduce accidents, even as the job may commence before sunrise or continue after sunset. Such apparel includes high-visibility vests and jackets. Long-sleeve shirts provide protection from weather elements – including sun exposure – and skin abrasions. Long pants instead of shorts provide an added layer of protection against skin abrasions and harmful UV rays. Overalls and coveralls also provide optimal protection.

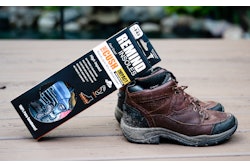

Gloves while OSHA notes gloves must not be worn when and where they can get caught in powered machinery, those in charge of worksite safety assessments can analyze worksite dangers to determine the appropriate gloves to make it easy to operate heavy machinery. Gloves not only enable a better grip on the excavator’s controls but can help protect hands from possible injuries and blisters. Steel-toed boots protect against potential injuries from feet coming into contact with falling or rolling heavy objects or other equipment on the jobsite.

Inspecting workwear at the beginning and end of the day helps ensure it will provide the proper protection for subsequent uses. As always, workwear should comply with established worksite safety standards.